Casting

Fire, earth, metal...

These are the elements of casting. Fire is used to melt metals, earth dams up the liquid embers and gives them shape and form, the variety of which is almost infinite...

Casting is one of the old metalworking techniques and is an interesting addition to forging.

The easiest way to pour is directly into the sand as an open cast. More demanding projects can be achieved with mould boxes or with the lost wax casting process...

Gieß-Kurs

mit Volker Allexi

(23-24.05.2025)

€500.00*

Free shipping

This product will be released on 22 May 2026

Questions - Answers - FAQ

Many questions about the topic of watering, to which we try to give answers and without meaningless AI texts.

Do you still have questions? Then please ask us directly here:

E-mail:

What is casting?

Casting is one of the main groups of primary molding and is a technique that was already used in prehistoric and early history.

Liquid material (molten metal) is poured into a mold and workpieces or objects are thus produced.

Casting is a perfect complement to forging and so, for example, fence tips can be quickly and easily reproduced by casting during a restoration.

What equipment is needed for casting?

In any case, you will need:

- Crucible

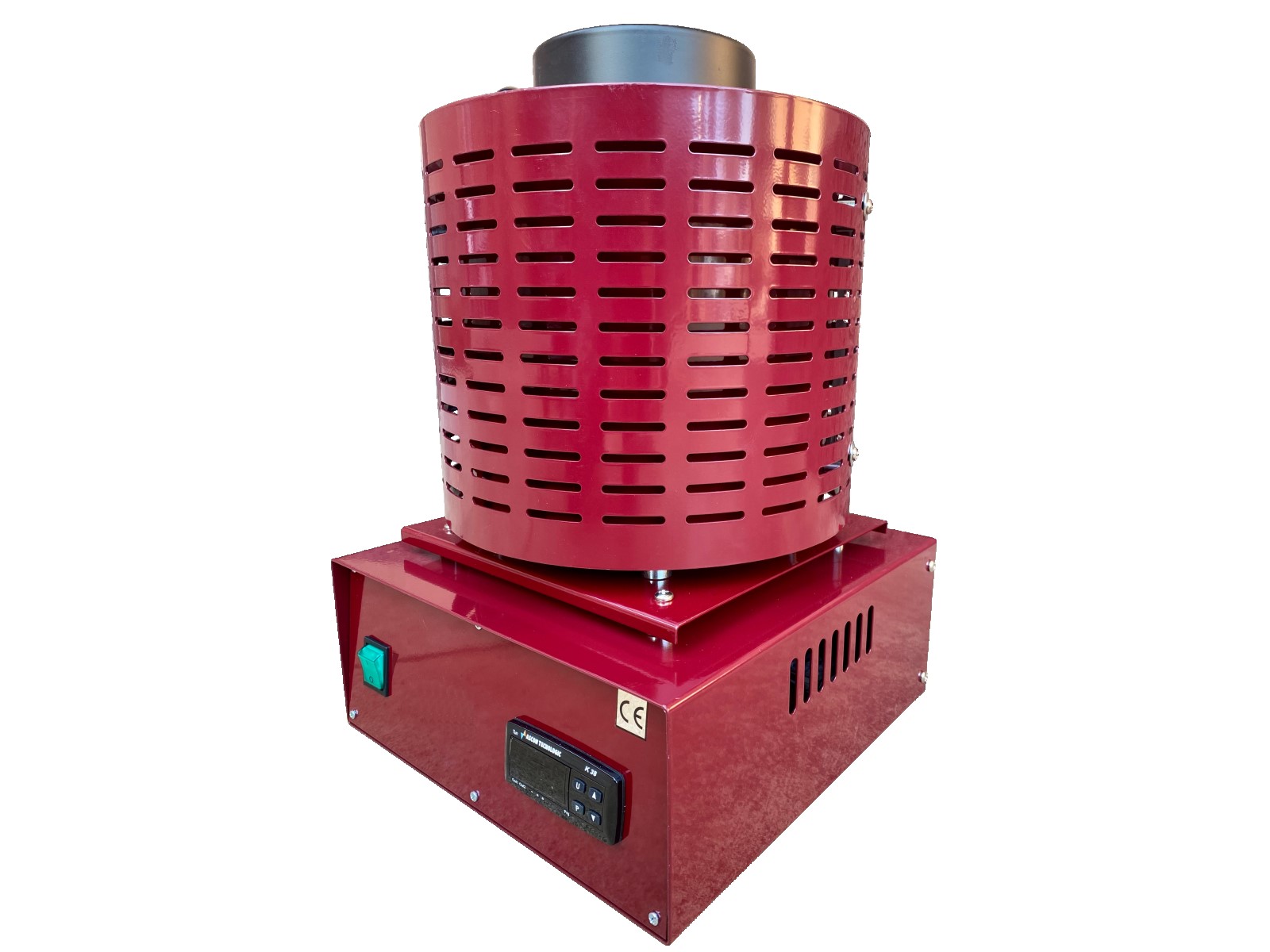

- Oven/fireplace

- Casting mold

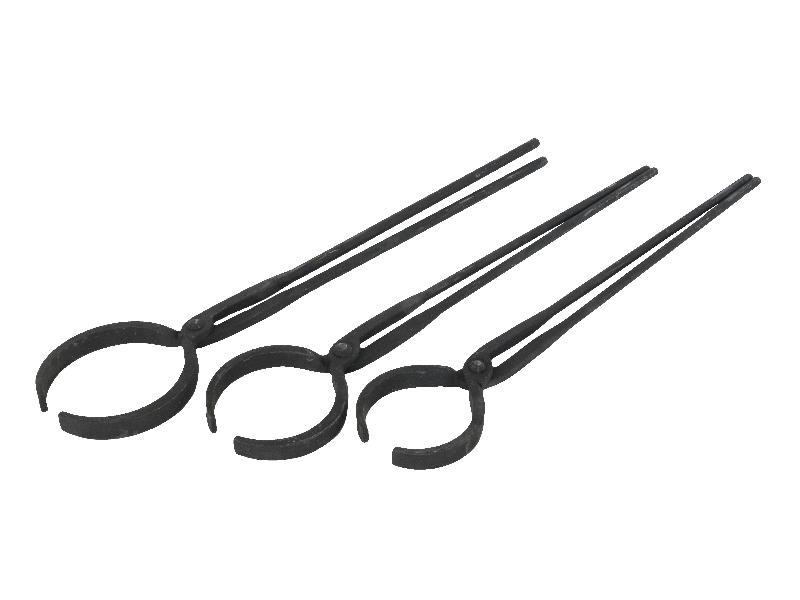

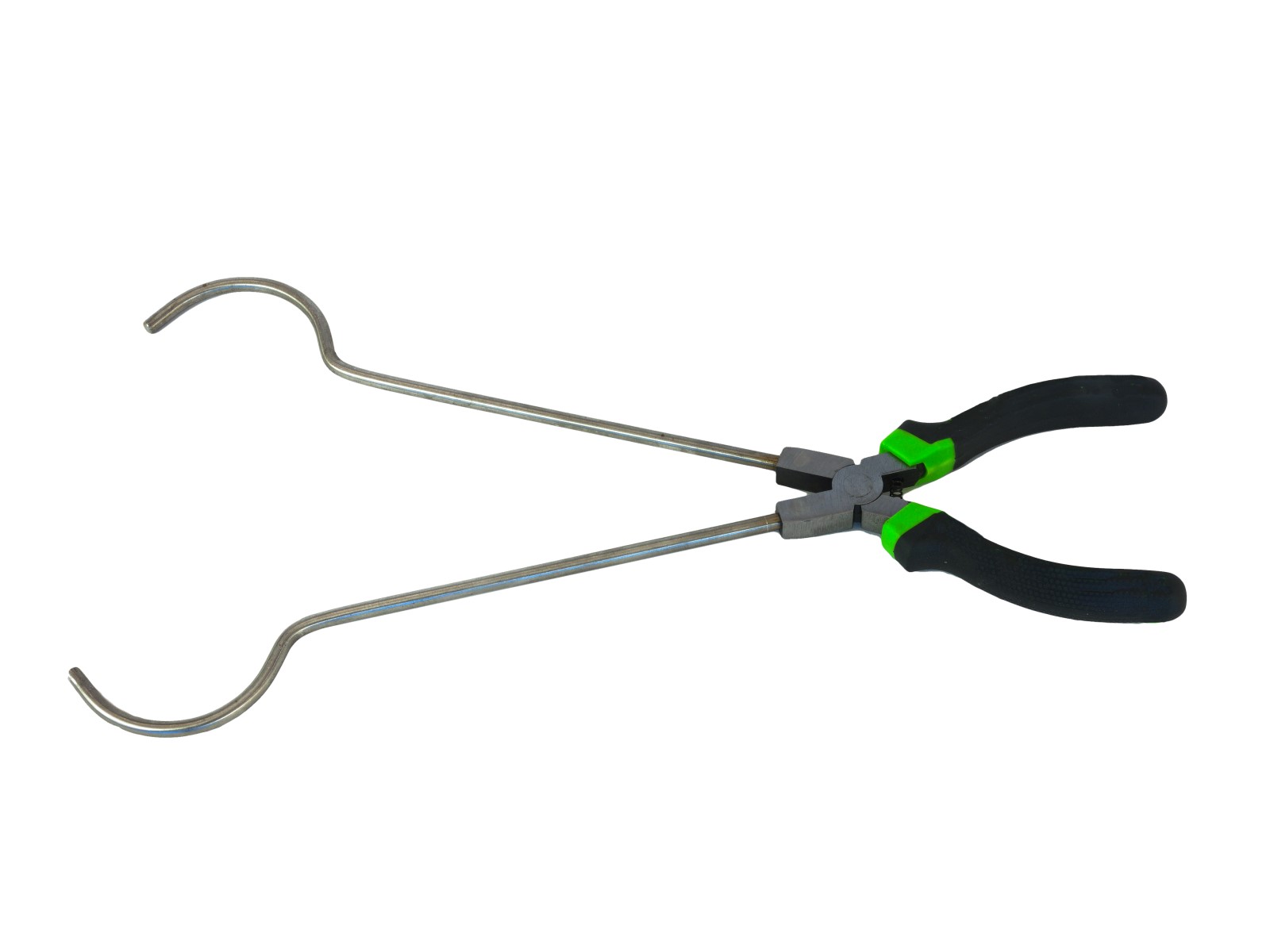

- Tongs

- Protective equipment

- Molding sand

Depending on the specific application, different techniques and tools are used.

Where can I buy foundry tools and accessories?

Of course you can get everything from us.

From furnaces to tongs to protective equipment, we offer you everything you need for casting from a single source in the best quality.

What do I need as a beginner to cast?

In principle, a crucible and a way to heat it are enough.

The crucible can then be poured out using suitable tongs.

The most important requirements are usually present in a forge.

For example, the crucible can be heated in a field forge.

Knee tongs can be used to pour out the crucible.

The molding sand can be obtained in small quantities

....and off you go

Can I cast with children or at school?

Casting is perfect for craft lessons.

With a few simple tools, pendants, brooches, and much more can be cast at low cost and with manageable effort.

The right protective equipment is of course important here.

Are you planning a project or are you interested in casting and forging in class?

Then contact us and we will support you.